What is Foam Filled Fender?

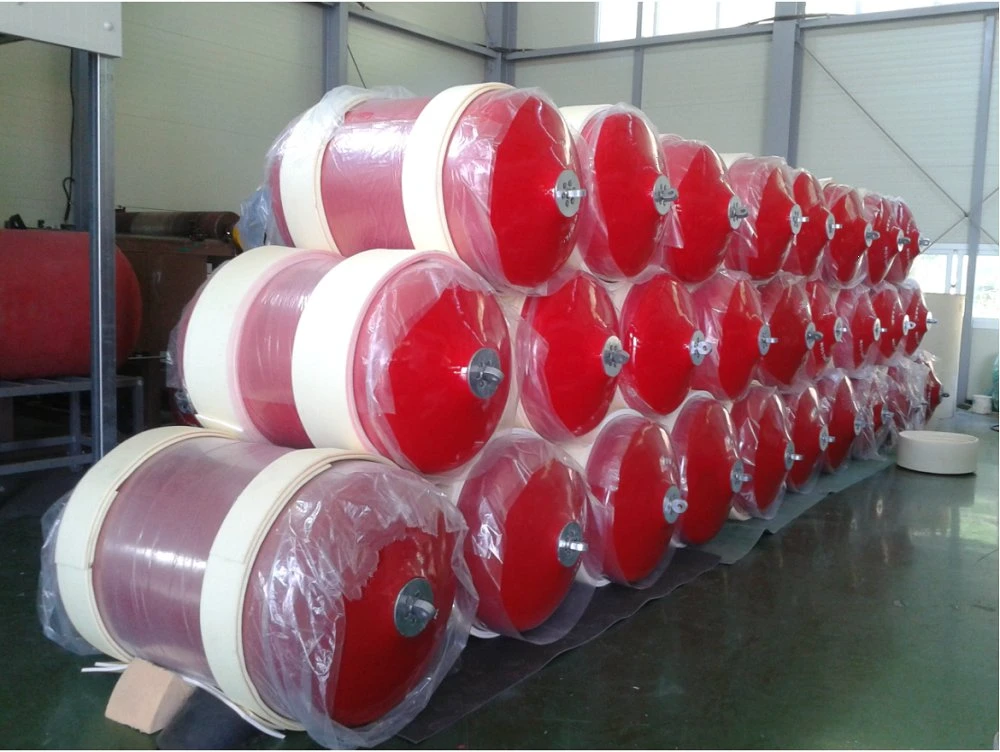

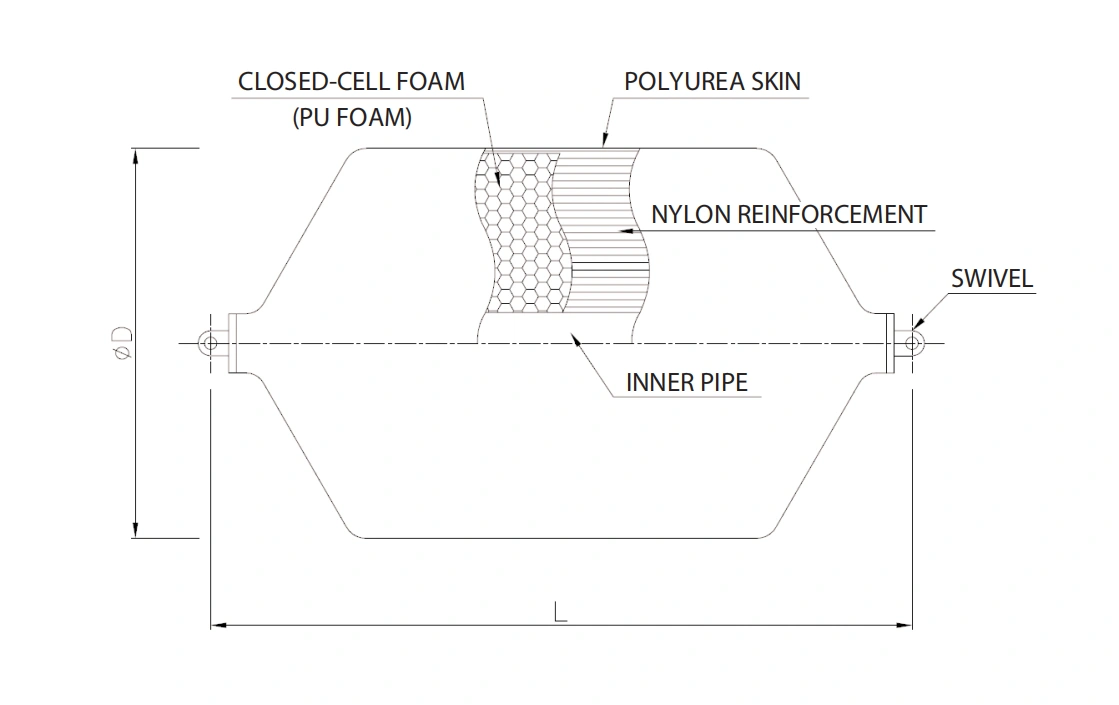

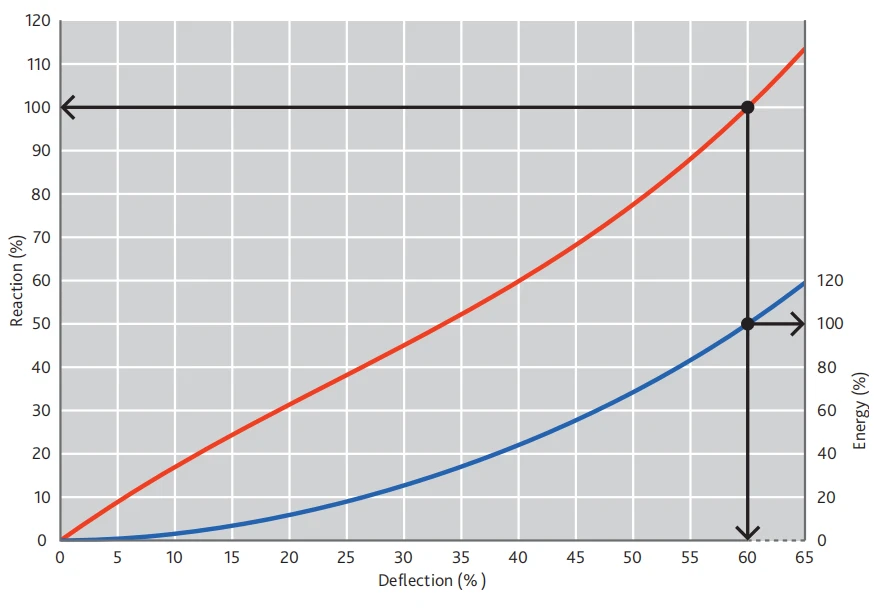

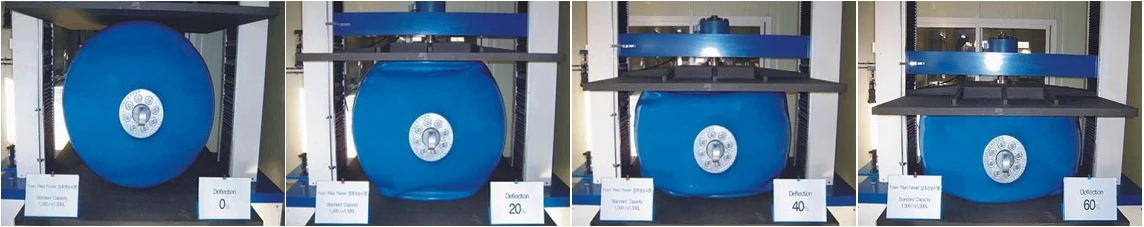

Jerryborg Marine uses heat-sealed foam for its fender core. The foam is fully enclosed and covered with a strong, reinforced polyurethane exterior. This feature makes the fender highly resistant to stress, allowing it to absorb large amounts of energy while operating at sea.

These foam-filled fenders have special insides to prevent overloading and manage docking pressure. They make mooring safer and simpler, even in rough weather.

They are available in various sizes, from 200mm to 4,500mm in diameter and 500mm to 10,600mm in length, and are designed to meet various maritime needs. They also come in different foam densities and shapes. Depending on the specific setup required, they can be installed using a two-point or four-point mounting system.